-

UTC experts had successfully accomplished thousands of failure analysis and accident investigation projects, some typical cases related to corrosion are listed as follows:

- Failure analysis on crevice corrosion of roller coaster vehicle spindle

- Forensic investigation on stainless steel wire rope snapping or breaking (fracture by stress corrosion cracking) of mass rapid transport system/ subway accident

- Failure analysis on corrosion and tarnish of electronic component leads

- Investigation on silver migration between PCB connecting fingers

- Failure analysis on aircraft air foil corrosion

- Investigation on corrosion caused by paint and coating failures

- Failure analysis and investigation on wire rope corrosion damage of crane and expert witness services

- Failure analysis on corrosion of large batch of doors

- Investigation on propeller bolt (fractured by corrosion fatigue) of hovercraft accident

- Failure analysis investigation on vehicle track bolt corrosion failure

- Forensic investigation on cooling pipe corrosion of jack-up rig

- Failure analysis on manhole corrosion damages

- Forensic investigation on corrosion and fracture of galvanized bolts in roller coaster track

- Failure analysis of oil an gas pipeline corrosion and expert witness services

- Investigation on corrosion of building structures etc.

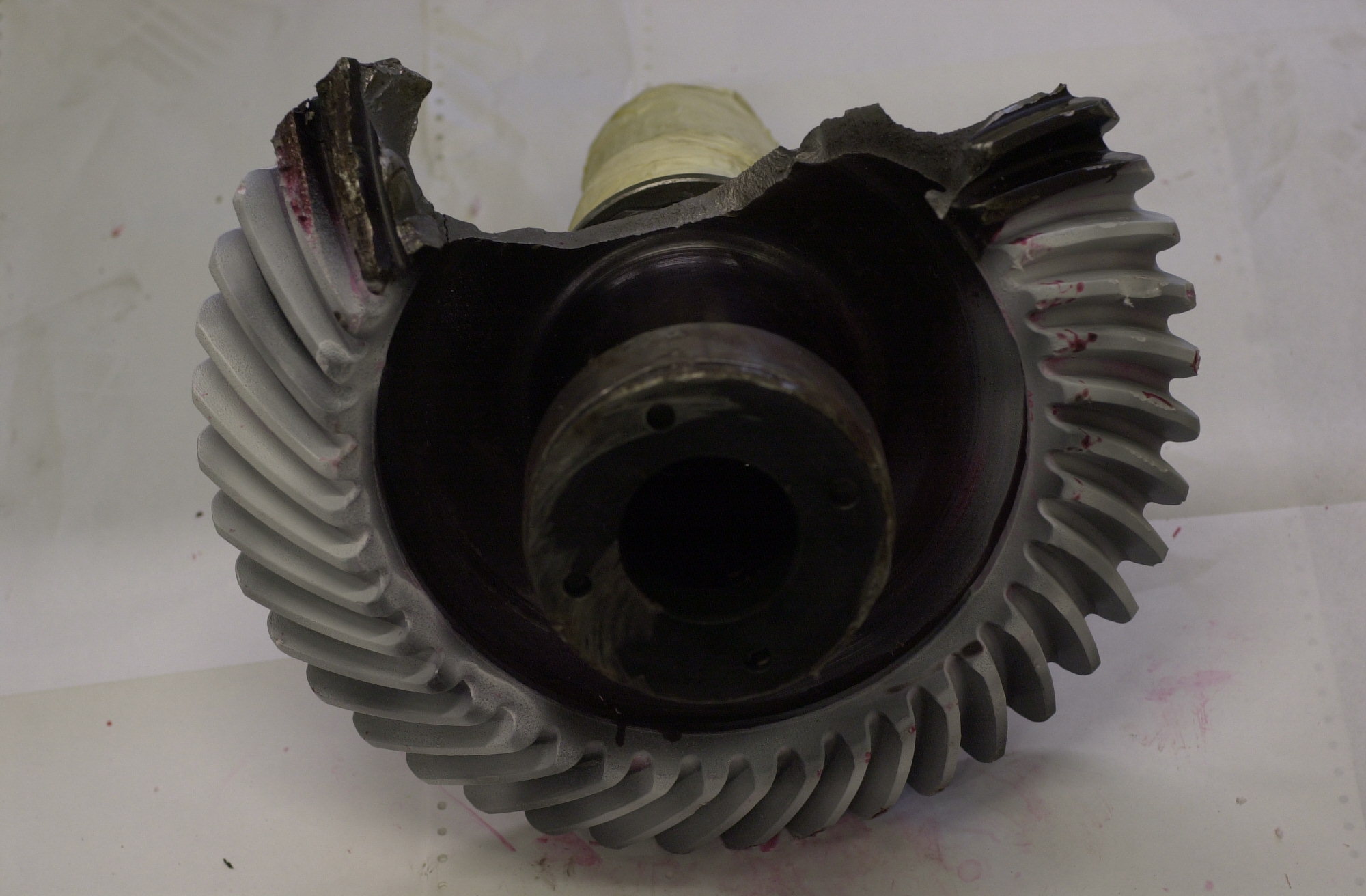

Cross sectional view of stress corrosion cracking (SCC)

Corrosion Failure Analysis, Prevention and Expert Witness Services in Singapore

What is corrosion?

Corrosion is degradation of metals through chemical or electrochemical reaction between metals and its environment. Typical example is oxidation of iron and steels, resulting in rust or corrosion products.

Corrosion occurs in all industries from automotive and aerospace to infrastructure, construction, marine, petroleum, oil & gas, power, paper making, food processing, bioengineering, and pharmaceuticals. Corrosion is costly, dangerous, wasteful, and unsightly in some cases.

What is corrosion engineering?The core of corrosion engineering is corrosion control and prevention, which includes conducting failure analysis and investigation on corroded parts to understand corrosion mechanisms and corrosion causes, and studying corrosion preventive methods to minimize or control corrosion.

Corrosion failure analysisCorrosion failure analysis (or corrosion failure investigation)is to adopts systematic analysis approach to determine root cause(s) and mechansim(s) of corrosion failure and provide counter measures to prevent similar corrosion failure recurrence.

Corrosion expert witnessCorrosion expert witness is a person with specialised and extensive knowledge in corrosion based on training, study or experience. Engaging corrosion expert witness services can be from the legal, insurance and industrial sectors as well as government agencies for assistance in settling lawsuits, litigations, arbitrations, safety related prosecution, construction disputes and insurance claims related to corrosion issues.

Corrosion expert witness may be required in litigation proceedings including Courts and tribunals to assist them in reaching a decision and justifications when the Courts require expert evidence. Corrosion expert witness provides expert opinions and evidences in their testimony mostly based on forensic investigation or analysis on the subject corrosion issues as well as scientific knowledge.

More details about expert witness, please refer to Expert Witness Services.

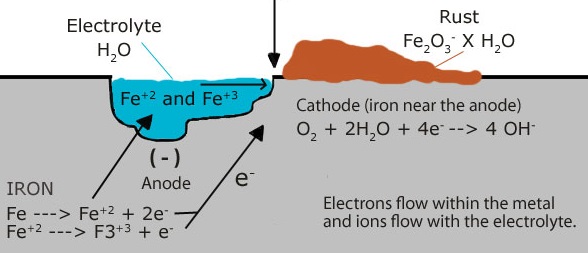

Corrosion processAs corrosion is chemical or electrochemical reaction between metals and environment, electrochemical cell(s) are formed in corrosion process. Four elements must be present for corrosion to occur.

- Anode: The site of metal where oxidation (corrosion) occurs

- Cathode: The site of metal where corrosion does not form

- Metallic pathway: Provides the flow of electrons from anode to cathode

- Electrolyte: A liquid that contains charged particles and allows ions to flow from cathode to anode

The interaction between these four elements is known as the corrosion cell. Three elements of corrosion are already present in most metals: anode, cathode and metallic pathway. Only missing element is the electrolyte that comes from the atmosphere or chemicals.

EMAIL or Call (+65)81380509 to contact UTC corrosion experts for assistance in consultation of corrosion problems.

UTC's corrosion investigation and analysis services

UTC team consists of corrosion experts with more than 35 years of relevant industrial and research experience as well as qualifications. The key staff has successfully led and completed thousands of consultation projects in forensic analysis, accident investigation, failure analysis, corrosion investigation & analysis, condition assessment and expert witness services for aerospace, marine, petrochemical, electronic and microelectronic, construction, amusement, oil & gas, transportation industries and governmental agencies including Ministry of Defence (Singapore), Republic of Singapore Air Force (RSAF), Defence Science and Technology Agency (DSTA), Singapore Civil Defence Force (SCDF), Ministry of Manpower (MOM), Hyundai Engineering and Construction (Korean), Public Utilities Board (PUB), The Straits Times, SBS Transit, High Court, State Courts, China Taiping Insurance, Rajah & Tann, WongPartnership, Universal Terminal, Singapore Navy, SMRT, RWS, Shell, ST Aerospace, Eagle Services Asia, SIA Engineering, HP, Dell, ST Marine, Takenaka Corporation (Japan) and Sembawang Shipyard, etc. Many projects are related to corrosion analysis and investigation.

Pitting corrosion of steel reaction with water

Typical corrosion related consultation projects

Investigation on metal sheet corrosion

UTC expert areas in corrosion engineering and expert witness

-

UTC provides professional services in following areas:

- Corrosion failure analysis investigation consultation

- Corrosion inspection and examination

- Investigation on damages and discoloration

- Corrosion prevention consultation

- Expert witness services for corrosion related failures and accidents

- Crane accident investigation and failure analysis

- Failure analysis services

- Forensic accident investigation Traffic accident reconstruction

- Fire investigation.

- Expert witness in litigation and insurance claims.

- Condition assessment

- Design and structural analysis

- Industrial technical training courses:

- Industrial Failure Analysis - Investigation, causes, mechanisms and prevention

- Applied Metallurgy - Compositions, microstructure, process and properties of metals and alloys

- Corrosion - mechanisms, investigation and prevention

- Fire Investigation

- Structual analysis in design and failure investigation

- Human factors in design and accident investigation

Other expert areas, please refer to

Our key experts had provided corrosion failure analyis, accident investigation, fire investigation and expert witness services to regional countries and beyond, including Singapore, Malaysia, China, Thailand, Philippines, Indonesia, India, Japan, Korean, The Netherland, Italy, etc.

Common corrosion forms and mechanisms

Corrosion prevention / control methods

- Corrosion prevention by proper design

- Corrosion control by materials selection

- Corrosion prevention by protective coatings Corrosion control by inhibitors

- Corrosion prevention by cathodic protection

- Corrosion Control by anodic protection

Content of UTC's corrosion training course

- Effects and Economic Impact of Corrosion

- Basic Important Concepts of Corrosion

- Eight Major Forms of Corrosion - general corrosion, stress corrosion cracking (SCC), crevice corrosion, pitting corrosion, galvanic corrosion intergranular corrosion, erosion corrosion and selective leaching

- Types of Corrosive Environments

- Principles of Aqueous Corrosion

- Atomsphere Corrosion

- Corrosion Characteristics of Structural Materials

- Corrosion Control by Proper Design

- Corrosion Control by Materials Selection

- Corrosion Control by Protective Coatings and Inhibitors

- Corrosion Control by Cathodic and Anodic Protection

- Corrosion Testing and Monitoring

- Failure Analysis on Corrosion

To know more about UTC's corrosion course, clickCorrosion course information

Recent relevant publications

-

Recently, UTC had published articles on failure analysis and accident investigation as follows:

- "Improving quality and reliabity through effective failure analysis" was presented in Symposium on Materials Processing, Inspection and Testing held on August 24, 2017, Malaysia.

- "Forensic investigation on crane accidents" was published in International Journal on Forensic Engineering in 2017.

- Hydrogen Embrittlement of Low Alloy Steels Under Cathodic Polarization

- Stress Corrosion Cracking of the Fusion Boundary for 304L/82 Dissimilar Metal Weld Joint

- Pitting Corrosion in Phosphor Bronze Tape Used in Underground Power Transmission Cables

- Failure Projection of Corroding Bridge Post-Tensioning Tendons

- Corrosion analysis of Materials after Advanced Surface Processing and Welding

- Review on corrosion inhibitors for steels in acidic media for the oil and gas industry

- Annalysis on oxidation and hot corrosion behavior of NiCrAlYSi+NiAl/cBN abrasive coating

- Temperature and applied strain on corrosion of X80 pipeline steel in chloride

- Investigation on atmospheric Corrosion of Carbon Steel, Aluminum, Copper and Zinc in Airport

- Investigation on durability of galvanised fasteners in timber construction

Click here to read more the presentation report.

Click here to read.

Objectives in corrosion engineering

-

Corrosion engineering achieves corrosion control and corrosion prevention by failure analysis on corrded parts and research on corrosion behaviours & law:

- Determine root cause(s) of corrosion.

- Find out mechanism(s) of corrosion.

- Recommend counter measures and solutions to prevent or minimize corrosion.

- As corrosion expert witness, support litigation/court hearing on liabilities related to corrosion failures and accidents

Click here to understand more about effective failure analysis and accident investigation.

Available analytical techniques for corrosion Investigtion

-

According to the project requirements, following techniques are available for assessment and failure analysis on corrosion projects:

- Scanning electron microscopy (SEM) to examine microscopic features of corrosion surfaces and pits.

- Energy Dispersive X-Ray spectrometry (EDX) to study chemical aspects of corrosion.

- Sectional metallography to examine material microstructure and relevance to corrosion.

- Tensile / Compressive test

- Charpy impact test

- X-ray diffraction (XRD) to identify type of corrosion products.

- X-ray photonelectron spectrometry (XPS) to chemical bonding of surface corrosion.

- Fourier transform infrared spectrometry (FTIR)

- Differential scanning calorimetry (DSC)

- Thermaogravimetry analysis (TGA)

- Ultrasonic Testing (UT)

- Radiographic Testing (RT)

- Liquid/dye Penetration Test (LT)

Contact our corrosion experts for consultation of corrosion issues, please click EMAIL or Call (+65)81380509 for more details.

Failure analysis services

Forensic accident investigation

Fire investigation

Traffic accident reconstruction

Expert witness in litigation

Corrosion engineering

Crane accident investigation & Failure analysis

Fatigue and fracture analysis

Design & structural analysis

Condition assessment

Failure analysis services

Forensic accident investigation

Fire investigation

Traffic accident reconstruction

Expert witness in litigation

Corrosion engineering

Crane accident investigation & Failure analysis

Fatigue and fracture analysis

Design & structural analysis

Condition assessment